Colorado Fuel Cell Center director and mechanical engineering professor Dr. Neal Sullivan and his team are testing Geothermic Fuel Cells (GFC) for a new application of solid-oxide fuel cell technology: heat generation. When placed underground within oil-shale formations, the heat naturally generated from the 750 ºC fuel cells is harnessed to liberate oil from the shale, known as “in situ oil shale processing.” The electricity generated by the fuel cells comes as a useful and valuable byproduct of the oil-recovery process.

Designed and built for IEP Technologies by Delphi Powertrain Systems, the world’s first geothermic fuel cell (GFC) operated continuously for five days at the CFCC in October 2013. During that time, the 6 feet by 1 foot in diameter GFC generated 3 kilowatts of electricity and 6 kW of heat. Follow-on testing in November reached power levels of 4.3 kWe. Both startup and operation of the GFC was thermally self-sustained.

Sullivan’s research team hopes to build on this laboratory-scale success through outdoor GFC operation scheduled for summer 2014. The outdoor tests will be on the Mines campus, and will utilize a significantly larger GFC measuring approximately 28 feet by one foot. It is expected to generate around 15 kW of electricity and up to 25 kW of heat.

Sullivan explained that the GFC recently tested in the CFCC could currently power one or two American homes. However, even a small oil production facility would require thousands of much larger GFCs. The target GFC size during deployment could reach nearly 500 feet in length. Industrial partner IEP Technologies estimates an 80,000 barrel-per-day oil field would require nearly 3,400 GFCs distributed in a network throughout the oil shale formation.

A field of GFCs of this magnitude would generate approximately 700 megawatts of electricity that could be sold back to the utility and put on the grid or provide power for operation of the oil field.

Research engineer Buddy Haun designed and built the extensive data-acquisition systems for the project, building test stands and taking advanced measurements to quantify GFC performance and behavior. Haun graduated from Mines in 1986 with a degree in petroleum engineering.

"I think this has potential to be a technology that alters the economics and political landscape in oil producing nations," Haun said. "We are using green technology to produce a product that is a lot more refine-able."

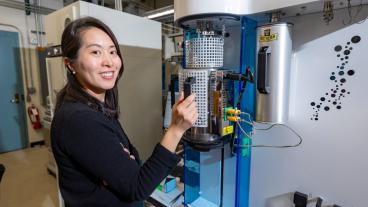

Graduate student Gladys Anyenya and Associate Professor Robert Braun apply computational models to explore relationships between the GFC operating conditions and the heating of the oil shale. Anyenya uses a chemical engineering program called Aspen Plus to predict electrical performance from the fuel cell. The current GFC in the lab has three stacks of fuel cells; the one underground will have nine.

"These models allow us to do things that we can't do with a physical experiment without the risk of damaging it," Anyenya said.

Research engineer Mark Daubenspeck is also part of the team and has played a central role in the construction of the GFC test stands. Daubenspeck graduated from Mines in 2011 with a bachelor’s degree in engineering physics and got his master’s degree in mechanical engineering in 2012.

Contact:

Kathleen Morton, Communications Coordinator / 303-273-3088 / KMorton@mines.edu

Karen Gilbert, Director of Public Relations / 303-273-3541 / KGilbert@mines.edu