Colorado School of Mines helping to guide industry forward to mine of the future

To meet critical mineral demand, the mining industry is adopting advanced technologies and new best practices that support a sustainable future

Many of the minerals necessary for powering the future — copper, lithium, nickel, cobalt and rare earth elements — are found underground. These are essential components of clean energy technologies, medical devices, defense systems, even cell phones. Global demand for these critical minerals has surged in recent years, requiring more mining.

However, the practices and technologies to source and extract these minerals — and those being considered for the future — are diverging from traditional methods. Modern mining techniques are taking what’s been described as a laparoscopic approach, emphasizing minimally invasive processes, for both the environment and surrounding communities.

“In response to an increasing demand for minerals, mining in the future will adapt and apply many new and developing technologies that drive increased productivity, enhanced safety and minimization of environmental impact,” said Bill Zisch, the J. Steven Whisler Head of Mining Engineering at Mines. By proactively addressing these challenges, Mines is helping guide the industry forward and shaping a new era of resource extraction.

Leveraging advanced technologies

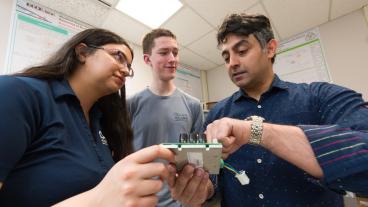

Advanced technologies are propelling the mining industry forward — to keep up with the critical mineral demand but also to improve processes and keep the industry economically viable. Mines researchers are working on many of the components of these advanced technologies, making them more efficient, more accurate and overall better tools for resource extraction and processing.

Some of the technologies being applied in the mining industry today include:

- Autonomous equipment and self-driving trucks to revolutionize haulage operations, increase efficiency and reduce operational costs.

- Remote-controlled machinery and robotics to enhance safety by minimizing personnel in hazardous environments.

- Advanced sensors to predict equipment failures, reducing downtime and maintenance costs.

- High-precision GPS and blast-movement monitoring, combined with machine learning, to improve the grade of material processed while minimizing dilution and ore losses to tailings.

- Artificial intelligence (AI) and machine learning to enhance ore sorting accuracy and increase efficiency. AI is also transforming exploration by improving geological data analysis, making it easier to identify potential mineral deposits.

- Digital twin technology, which is being deployed in mineral processing, allowing for the evaluation of control strategies in response to variations in feed and operating conditions, leading to improved efficiency.

“Meeting the materials challenge will require virtually every discipline at Mines,” Zisch said. “Autonomous mining equipment is designed and developed by engineers in the mechanical and electrical engineering field along with expertise from computer science. Solution mining advances requires expertise from petroleum and chemical and hydrogeologic engineering. Permitting of future projects requires contributions from environmental and humanitarian engineering. Tailings design, development and management will require geotechnical expertise from civil engineering. Mineral economics provide a unique contribution based on their understanding of markets, resource availability, policy development and economics. Advanced power systems help to solve the challenges associated with providing power to mining operations that will likely have to be self-sufficient anywhere in the world where they operate. Mines, as a university and across campus, is in a unique position to meet this challenge.”

Updating environmental considerations and best practices

The mining industry is also updating and implementing best practices that emphasize responsible mining, community engagement, transparency and social license to operate. This holistic approach ensures that mining operations are not only economically viable but also environmentally and socially responsible.

Researchers at Mines are leading this work by collaborating across disciplines to ensure extractive industries play a critical role in contributing to sustainable development in and around the communities in which they operate. As examples, researchers are working on projects that address the opportunities and challenges of small-scale gold mining in Colombia and Peru and projects that look at how industry can better assess and standardize their contributions to sustainable development.

Mines has also evolved its curriculum to reflect these priorities. Starting at the undergraduate level, students focus on sustainability, responsible mining and community engagement in their courses. This ensures that future engineers are equipped with the knowledge and skills to address the industry’s most pressing environmental and community challenges.

Developing a highly skilled workforce

t’s estimated that half of the U.S. mining workforce, about 220,000 people, will retire by the end of the decade, and the talent pipeline is not sufficient to replace experienced mining professionals or meet demand. This challenge, combined with the need for engineers capable of leveraging advanced technologies and addressing environmental and social considerations in future projects, is one Mines is rising to meet.

“Mines is continuing to adapt to a rapidly changing world,” Zisch said. “First, and perhaps foremost, students are learning basic engineering and problem-solving skills that are preparing them to meet these challenges. Additionally, significant, broad and creative research is helping to address these challenges and to prepare students for future challenges.”

Mines’ industry partners consistently look for talent from various disciplines, including expertise in mechanical, electrical, civil, environmental, chemical, petroleum and humanitarian engineering. But they’re also needing skills in economics, computer science, data science, risk management, statistics and mathematics. As a result, Mines graduates are highly sought after by industry, academia and government and serve in roles that include mine planning, extraction and processing, mine remediation and reclamation, community engagement, business and finance, public policy, regulatory compliance and more.