Colorado School of Mines students developing lunar “lily pad” for 2021 NASA BIG Idea Challenge

Students in Space Resources Program receive NASA funding to design, test dust-free landing pad

A team of Colorado School of Mines students have received funding from NASA to design and test a near-term solution to one of the biggest (smallest) challenges to future lunar exploration.

Moon dust.

The mostly small particles from the Moon’s surface kicked up by landing spacecraft are both extremely abrasive to equipment and extremely dangerous to astronaut’s lungs. And the bigger the lander, the bigger the dust cloud.

“When a 5-ton lander like the Apollo Lunar Module touched down, it blew out something like 2.6 tons of material,” said Travis Vazansky, a graduate certificate student in the Space Resources Program. “The next-generation Artemis lunar landers are going to be something on the order of 40 tons. You’re talking 108 tons of materials.”

“It’s like rubbing sandpaper over millions of dollars in instruments,” said Bailey Burns ‘18, now a master’s student in space resources.

Mines is one of seven collegiate teams working on real-world solutions to NASA’s space technology hurdles as part of the space agency’s 2021 Breakthrough, Innovative, and Game-changing (BIG) Idea Challenge.

This year’s challenge focuses on both active dust mitigation, like air filtration systems, and passive concepts, like dust-free landing pads and workspaces.

“The ideas out there already are super incredible, like 3-D printing landing pads with regolith,” Burns said. “But Artemis is three years from now. We don't know how to 3-D print using lunar regolith yet. This needs to be something we can do now, not in 10 years when we finally have the technology.”

The Mines team is collaborating with three industry partners – ICON, Masten Space Systems and Adherent Technologies Inc. – on their project, a dust-busting landing pad that could be rolled out like a red carpet for arriving spacecraft.

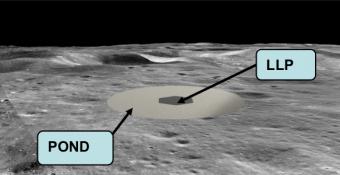

The Lunar In-Situ Landing/Launch Environment Pad, or LILL-E Pad, consists of two parts: A carbon fiber fabric landing “pad” that is anchored to a larger “POND” of polymer-reinforced regolith.

The inspiration for LILL-E Pad came from the U.S. Marine Corps, which uses a similar light-weight blanket when landing helicopters in dusty desert environments.

“Carbon fiber is lightweight and resistant to heat,” said Vazansky, who served in the U.S. Air Force as a civil engineering officer. “We’re just talking about basic carbon fiber fabric – you’re able to roll it out like a blanket and you can land the craft on it, trapping the regolith beneath.”

That center “pad,” with a 25-meter radius, would sit in the middle of a 100-meter radius “pond,” created by laying down a specialized polymer to harden the regolith and further mitigate dust.

“There are three companies working on a lunar lander and we’re not tied to any one of them – this technology could benefit all three of them,” Burns said.

All seven teams will present the results of their research and development to a panel of NASA and industry subject matter experts in November 2021.

Before then, the Mines team will be focused on finalizing the design and doing initial testing. The next deliverable to NASA is due in May and by then, they hope to have fleshed out the “pond” design and completed the thermal load and vacuum chamber testing on the carbon fiber “pond.”

Later this year, the Mines team will conduct an engine test with partner Masten Space System. The polymer they’re using for the “pond” was proposed by partner Adherent Technologies to NASA about 10 years ago.

Rounding out the Mines team are fellow Space Resources graduate students Miguel Coto, Nathan Davis, Sterling Loza, Thao Nguyen, David Purcell and Jon Slavik.

“We really think this is going to be a viable solution,” Burns said. “This story isn’t going to end in November. We want to take this to the Moon and do what we said we’re going to do and mitigate dust."