Mines researchers harnessing data to discover and design materials

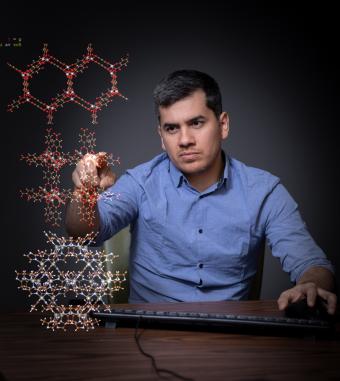

Researchers at Mines, like Chemical and Biological Engineering Associate Professor Diego Gomez-Gualdrón, are using machine-learning models and advanced computation to accelerate findings in material science.

By Anna Squires, Special to Mines Research Magazine

Chemical separations, such as the processes that fuel water purification and oil refining, are among the most energy-intensive processes on Earth. They’re necessary, but costly. But what if you could use artificial intelligence to reduce the energy they require tenfold?

That’s a question at the heart of nanosponge research by Diego Gomez-Gualdrón, associate professor of chemical and biological engineering. And it’s emblematic of research underway at the National Science Foundation’s Institute for Data-Driven Dynamical Design (ID4), housed at Mines, which aims to accelerate findings in material science by harnessing artificial intelligence.

Gomez-Gualdrón’s work on nanosponges — which can be made of materials known as metal organic frameworks — centers on their porous nature, just like the sponge in your kitchen. But nanosponges can be formulated to attract specific molecules while leaving others behind. The right nanosponge, exposed to a mixture, can extract the components of interest using 10 times less energy than traditional methods.

“The problem is that exhaustively synthesizing and testing nanosponges until one finds the right nanosponge for every separation in the chemical industry would require trillions of experiments — an impossible gambit,” Gomez-Gualdrón said. That’s why his research leverages machine learning, which can predict the separation properties of millions of materials nearly instantaneously. At play is not just a significant reduction of global energy expenditure. It is also the potential reduction of a trillion-year project into an instant — and an entirely new predictive method, offered as open-source software for fellow scientists.

“We want a machine learning model that can instantly predict adsorption of any molecule at any process condition. The idea of a ‘universal’ equation that would predict adsorption in any scenario was first pursued in the early 20th century, but the equation was becoming too cumbersome,” Gomez-Gualdrón said. “With our current ability to generate and collect lots of adsorption data, machine learning now seems like a plausible way to achieve the same goal."

This is just one of the transformative research projects underway at ID4. The cross-cutting collaboration, funded with $15 million from the National Science Foundation, has brought together data scientists, engineers, physicists, chemists and material scientists from 12 institutions across the U.S. Fueled by Mines’ materials science program, ID4’s goal is to harness the power of advanced computation and artificial intelligence to accelerate discovery in material science. It aims to push experimentation to the speed of theory—and along the way, create visionary new technologies for industrial and commercial use.

It’s a lofty ambition. But Eric Toberer, professor of physics and director of ID4, breaks it down to a question of tools.

“When we were creating the seedling of the idea that became ID4, we asked ourselves, ‘What are the problems that have historically felt extremely intractable, but with advances in computation and machine learning, is there an opportunity to move the needle? And how could we bring in human expertise and artificial intelligence jointly to address these problems?’ ” Toberer said.

“Computation today is producing more data than the human brain can comprehend,” he continued. “And we need tools to help us make good decisions in physical sciences and engineering, given this giant wave of complicated data. This Institute is about building those tools.”

The engine at the core of ID4 is its interdisciplinary faculty. Inspired by the Materials Genome Initiative, an Obama-era project that partnered experimental and computational researchers to discover material twice as fast as traditional methods, ID4 brings together both material and data scientists who collaborate across four material science sub-domains and on core data science needs.

“If the Materials Genome Initiative had never happened, we never would have become the scientists we are, who could conceptualize being part of this Institute,” Toberer said. “When you do collaborative research between computational groups and experimental groups, you create findings that are more than just the sum of the two parts."

That collaboration explains how the Institute is poised to transform the methods and speed at which we discover materials — and tackle some of the world’s most pressing challenges along the way. Gomez-Gualdrón’s nanosponge research, for instance, could have an impact on methods to trap C02. The Institute’s photocatalysis researchers are working to create sustainable chemical reactions by harnessing visible light as fuel. Its ion-trapping group will be critical in creating next-generation solid-state batteries, electrolyzers and fuel cells.

“At the end of these five years, we should have a toolkit full of hammers,” Toberer said. “At the end of 10 years, I hope we’re still smashing away with those hammers. There are just so many ways in which you could imagine adoption of our work. For us, a victory would be creating things that the broader scientific community uses on a daily basis and arming our collaborators, in whatever space they’re in, with tools to understand complicated systems and then build better ones.”

Learn more about the transformative work happening at the Institute for Data-Driven Dynamical Design at mines.edu/id4.