Mines researchers awarded $7.7M from ARPA-E to test full-scale hybrid stationary power system

Fuel cell researchers at Colorado School of Mines have been awarded $7.7 million in funding from the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) to develop and test a full-scale hybrid stationary power system that could provide highly efficient electricity to hospitals, supermarkets, large retailers and more.

“We’re targeting the highest electric efficiency ever for something that’s powered by a fossil fuel – the world’s first 70 percent efficient natural-gas fueled power generation system,” said Robert Braun, professor of mechanical engineering and principal investigator on the ARPA-E project. “It’s natural gas, but it’s clean and there are very few emissions other than carbon dioxide.”

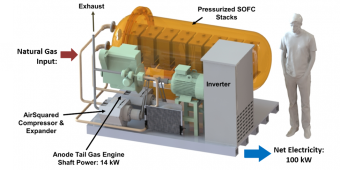

The system, which was developed by Braun’s team at Mines, integrates pressurized solid oxide fuel cells with a highly efficient stationary engine fueled by pipeline natural gas – a combination that both increases the efficiency and lowers the cost of power generation.

Collaborating on the project are researchers from Colorado State University and industry partners Kohler Power Systems and Air Squared Inc.

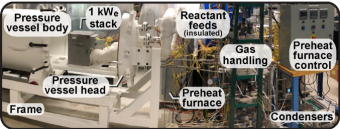

“In Phase One of the project, we’ve spent almost two years designing the hybrid system, the controls, and developing all the hardware,” Braun said. “The next step in Phase Two is to develop second-generation versions of all that hardware, assemble it into an integrated system and test it at full-scale to prove out the technology.”

That testing will occur on the microgrid at CSU’s Powerhouse facility. The hybrid system should be capable of generating 100 kilowatts of electric power at an unprecedented 70 percent electric efficiency.

“The highest efficiency fuel cell device right now is around 60 percent at beginning of life. By the end of its life, it may not be that efficient any more or it may deliver less power than it did at the beginning,” Braun said. “This is going to be 10 points higher efficiency than that and at lower cost. That efficiency is also 10 points higher than the best combined cycle power plants available today.”

The type of fuel cell the system uses – a metal supported solid oxide – is a major factor in its lower cost, robustness, and unparalleled efficiency, Braun said. “We are also pressurizing this fuel cell and testing its performance in our facility at Mines, he said. “Most high temperature fuel cells operate at near ambient pressure and an important aspect to achieving high efficiency is to operate the devices slightly pressurized.”

Historically, high capital cost and poor durability have been significant barriers for solid oxide fuel cell technology to achieve widespread adoption in commercial distributed power generation applications. In part, these challenges have historically been associated with their high operating temperatures (750-1000°C).

“In addition to some pressurization, our fuel cells operate at 200 degrees Celsius cooler than the more traditional solid oxide fuel cells, such as those by Bloom Energy, which are the most prevalent right now,” he said. “By virtue of that lower temperature, much of the balance of plant equipment – heat exchanges and plumbing – can use lower-cost materials and the heat exchange duties are lower. You can use less expensive materials and the sizes are smaller because you don’t have to heat things up to 800 degrees C.”

Potential users of the hybrid system could include hospitals, schools, supermarkets, data centers and large retailers looking for distributed generation of baseload power.

Also working on the project at Mines are Neal Sullivan, associate professor of mechanical engineering who is leading the pressurized fuel cell testing; and Tyrone Vincent, professor of electrical engineering, who is leading the controls development. With this new Phase 2 award, total project funding amounts to $10.8M over five years and will fund over nine graduate students, two post-docs, and eleven engineers and technicians across the entire team.