Putting ‘Pepto’ into the belly of a boiler

Building a smart robot to inspect, repair power plant boilers

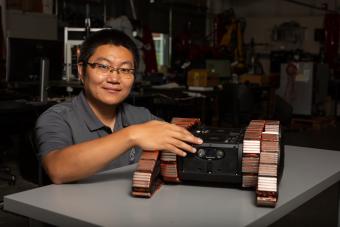

Hao Zhang, Mines assistant professor of computer science leads a team of researchers developing smart robots for maintaining power plant boilers.

Boilers are one of the most critical components in a thermal power plant, but inspecting and repairing them is no easy task.

Today, the only method involves costly scaffolding and human inspectors, all crammed inside the hazardous, confined environment of the boiler itself. If left unchecked, damage to the boiler furnace chamber can cause catastrophic failures.

But what if an autonomous robot could scoot up the boiler walls, inspecting the surface and making live repairs as it goes?

That’s exactly what Hao Zhang, assistant professor of computer science, and an interdisciplinary team of researchers are developing, with funding from the U.S. Department of Energy’s Office of Fuel Energy. Also contributing to the project are Andrew Petruska, assistant professor of mechanical engineering; Zhenzhen Yu, assistant professor of metallurgical and materials engineering; and Yiming Deng of Michigan State University.

We sat down with Zhang to talk about how smart robots can revolutionize energy site maintenance methods.

Q: How did the DOE funding come about, and what do they want from the project?

Hao Zhang: DOE puts out funding opportunities to address the most critical challenges in industry, and it turns out, one of the key problems they are trying to solve is how to inspect these tall coal-fired power plant boilers. Their goal is to find autonomous robotic solutions that are capable of doing the inspections and/or doing the repairs. Mines is the only awardee that’s addressing the repair problem.

Q: What are the benefits of using robots in power plant boilers?

Zhang: The first benefit is safety. One of the biggest issues they have now is fall risk and having humans working in a hazardous environment for a prolonged period of time. It can take several days of work to install the scaffolding, and then the inspection takes another few weeks.

The second benefit is to reduce the cost. Today, we need to shut down the power plant to do the scaffolding and inspections. We won’t need to do scaffolding in the future—the robot can just crawl on the boiler wall—reducing the cost and increasing the frequency of inspection.

Q: Why does this type of research interest you?

Zhang: It’s a very interesting problem—there’s a huge market out there, but there’s no solution yet.

It’s highly interdisciplinary, too. On the team, we have computer science, mechanical engineering, materials science and electrical engineering, and we have industry collaborators.

A lot of coal-fired boilers have been operating for over 40 years. We will see more failures there. It’s a really good time to have some autonomous robotic solutions that can do the inspections and repairs more frequently.

Q: What are the challenges you have to confront?

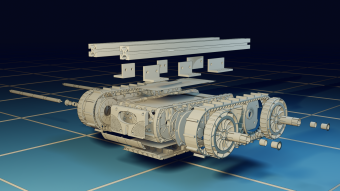

Zhang: On the platform side, the challenge is to make the repair tool small enough to put on a robot. These repair tools are large in size and often pricey. We’re trying to make it less than 1 foot.

The other challenge is the robot design. We need to integrate the repair tools and nondestructive sensors on a robot that must also have magnetic tracks so it can navigate on the boiler. It’s possible that the magnetics could impact the sensor signals. So, we need to figure out how to put all these components together on one platform.

On the software side, the biggest challenge is implementing the artificial intelligence. We need our AI to be able to integrate all the information, recognize any damage and create a 3D map and localize the damage. At the same time, the AI has to be able to navigate the robot autonomously and control the repair tool.

Q: Why were you insistent on engaging students on the project?

Zhang: It’s critical for the next generation of roboticists and scientists to appreciate the real-world challenges and beauty of robot intelligence to solve these big social and economic problems. This project is a really good opportunity for students to work in an interdisciplinary research team with four professors from different departments and talk with industry collaborators and get a broader picture and broader vision of what’s going on.